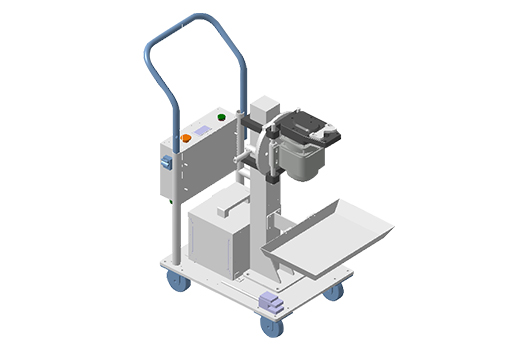

Product Introduction

The Automatic Projection Welding Electrode Grinding Machine is a fully automatic electrode grinding machine designed for projection welding machines on automotive body production lines. It can automatically grind projection welding electrodes without manual intervention, automatically avoiding the workpiece during welding and grinding the electrodes after welding, thereby improving the automation rate of the production line. This product uses carbide coated inserts, enabling high-speed grinding and simultaneous grinding of both upper and lower electrodes of the projection welding machine, resulting in a bright and smooth electrode end face after grinding.

Product Features

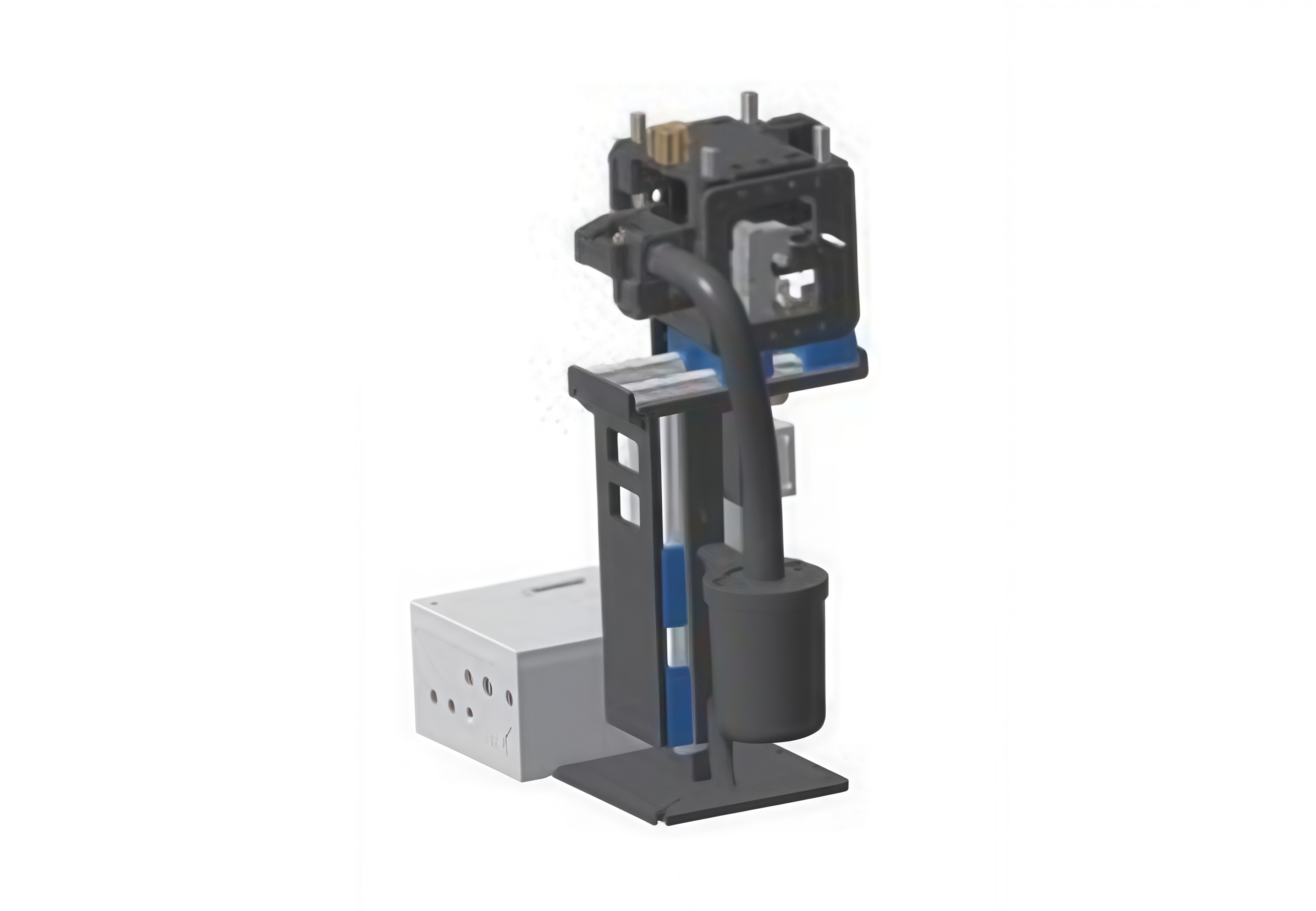

- High Torque Grinding: Driven by a 380V servo motor, the grinding speed is adjustable, and it can automatically grind projection welding electrodes with a maximum outer diameter of Φ35.

- Composite Motion Mechanism: Equipped with a lifting and translation slide table, driven by a cross cylinder, it allows the grinding body to perform precise movements in two vertical directions to adapt to actual working conditions, and automatically resets after grinding.

- Intelligent Buffer Compensation: An internal buffer spring cushions the impact force when the welding clamp tightens, preventing damage to the equipment; it also automatically compensates for distance changes caused by electrode shortening during grinding, preventing over-grinding.

- Fully Automatic Operation Cycle: Enables a fully automated workflow from avoiding the welding position, moving to the grinding position, applying pressure compensation, grinding, and resetting.

- Industrial-Grade Communication Integration: Equipped with external ports to meet various field communication requirements; standard ports include Profinet, with optional hardwired I/O.

在线联系

在线联系