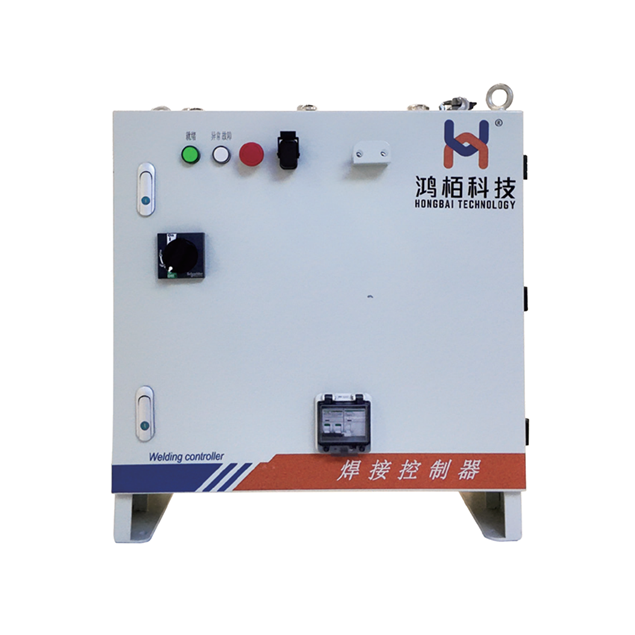

Product Introduction

This spot welding machine uses a fully digital power supply and a high-speed DSP microprocessor, which has strong information processing capabilities. The control system has been enhanced with an adaptive function, which has a large adaptive range and strong robustness. One welding clamp can adapt to the welding needs of plates of different thicknesses at one workstation, and has a wide range of applications. It can be used for welding ordinary cold-rolled plates, galvanized plates, hot-formed steel plates, and high-strength plates. It is mainly used in automotive body welding production lines (such as SAIC Volkswagen, GM, FAW-Volkswagen, etc.) to achieve automated welding of high-strength steel plates, multi-layer plates and aluminum plates.

Key features of the product

1. The transformer is small in size and lightweight, achieving integrated operation of the transformer and welding gun, and reducing the load requirements of the welding robot. 2. Adaptive control of welding pressure and welding current allows a single welding gun to perform welding operations on multiple workpieces of different thicknesses at the same workstation. 3. The welding gun servo mechanism can be equipped with a hollow electric cylinder specially developed by our company for robotic spot welding machines, and is also compatible with current mainstream servo drive products; it can be widely used in various types of welding robots. 4. The welding gun body structure, which has obtained multiple appearance patents, is precision-machined from aerospace-grade aluminum and high-quality copper, featuring high rigidity, high strength, small deformation, and good conductivity, highlighting the stability and safety performance of the equipment. 5. The welding controller has good power grid adaptability and strong anti-interference capability. 6. It integrates a wide range of protocol interfaces and can be configured according to user-defined personalized needs. 7. Two main types of welding guns (C-type and X-type) can reliably connect with most domestic and foreign industrial robots to meet the needs of different fields and users.

Product Specifications

| 方面 | 810mm×685mm×480mm |

|---|---|

| 输入特性 | Three-phase 380V±15% 50~60Hz |

| 输出特性 | 540V±15% (1&2)kHz |

| 额定负载电流(A) | 450A |

| Maximum Load Current (A) | 600A |

| 绝缘等级 | F |

| Operating Mode | Welding robot linkage |

| 冷却方式 | Forced air cooling |

| 重量 | 85kg |

| Rated Output Power (KW) | 180kW |

| Inverter Frequency (Hz) | 1-2Hz |

| 额定负载率 | 20% |

| No-load Loss (KW) | ≤0.07kWh |

| 防护等级 | IP54 |

| Welding Clamp Interface (Type C or Type X): | |

| Compatible Transformer Models | BJ1-105, BJ1-135, BJ1-175, BJ2-105, BJ2-135, BJ2-175 |

在线联系

在线联系