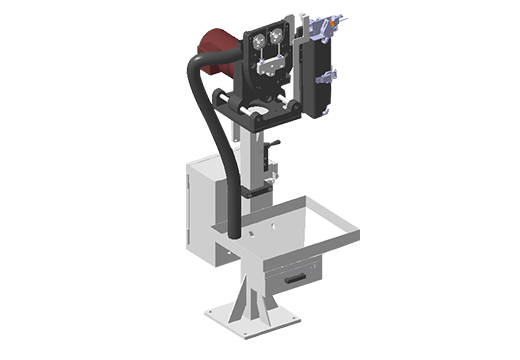

Product Core

- Improved Welding Efficiency: Automatically replenishes studs for the semi-automatic servo welding torch, enabling uninterrupted continuous welding operations and significantly improving production efficiency.

- Ensuring Stable Quality: Stable and automated feeding, combined with precise control of the welding torch and the main unit, ensures consistency between the welding process and the final quality.

- Modular and Flexible Adaptability: Adopting a modular design, it can quickly adapt to different specifications (diameter 3~12mm) and types of studs by replacing parts, offering strong versatility.

- Integrated Intelligent Control: Connects to the welding main unit (such as the SAW-3600 series) via a dedicated communication protocol (such as Max485), enabling real-time interaction of commands and signals, and providing a clear and intuitive understanding of the operating status.

- Compact and Reliable Structure: Integrates the hopper, loading mechanism, air circuit, and electrical control system in a compact design (approximately 345×331×445mm), ensuring stable operation and clear maintenance requirements.

| Operating Power | AC: 220V 50/60Hz |

|---|---|

| Rated Power | W |

| Operating Mode | Semi-automatic/Automatic |

| Stud Conveying Speed | Pieces/min |

| Supported Stud Types | Standard, T-type, Special-shaped |

| Stud Welding Diameter | 3-12毫米 |

| Drum Drive Method | AC Motor |

| Motor Rated Voltage | |

| Drum Filling Capacity | 1000-3000 pieces, depending on stud type |

| Motor Rated Current | |

| Compressed Gas Input | 0.6MPa (-10%/+30%), manually adjusted via pressure regulating valve knob |

| Protective Gas | Not Supported |

| Compressed Gas Input | |

| Protective Gas | |

| Internal Communication | |

| External Communication | |

| Operating Temperature | |

| Operating Humidity | |

| 方面 | |

| 重量 | Approx. 35KG |

在线联系

在线联系