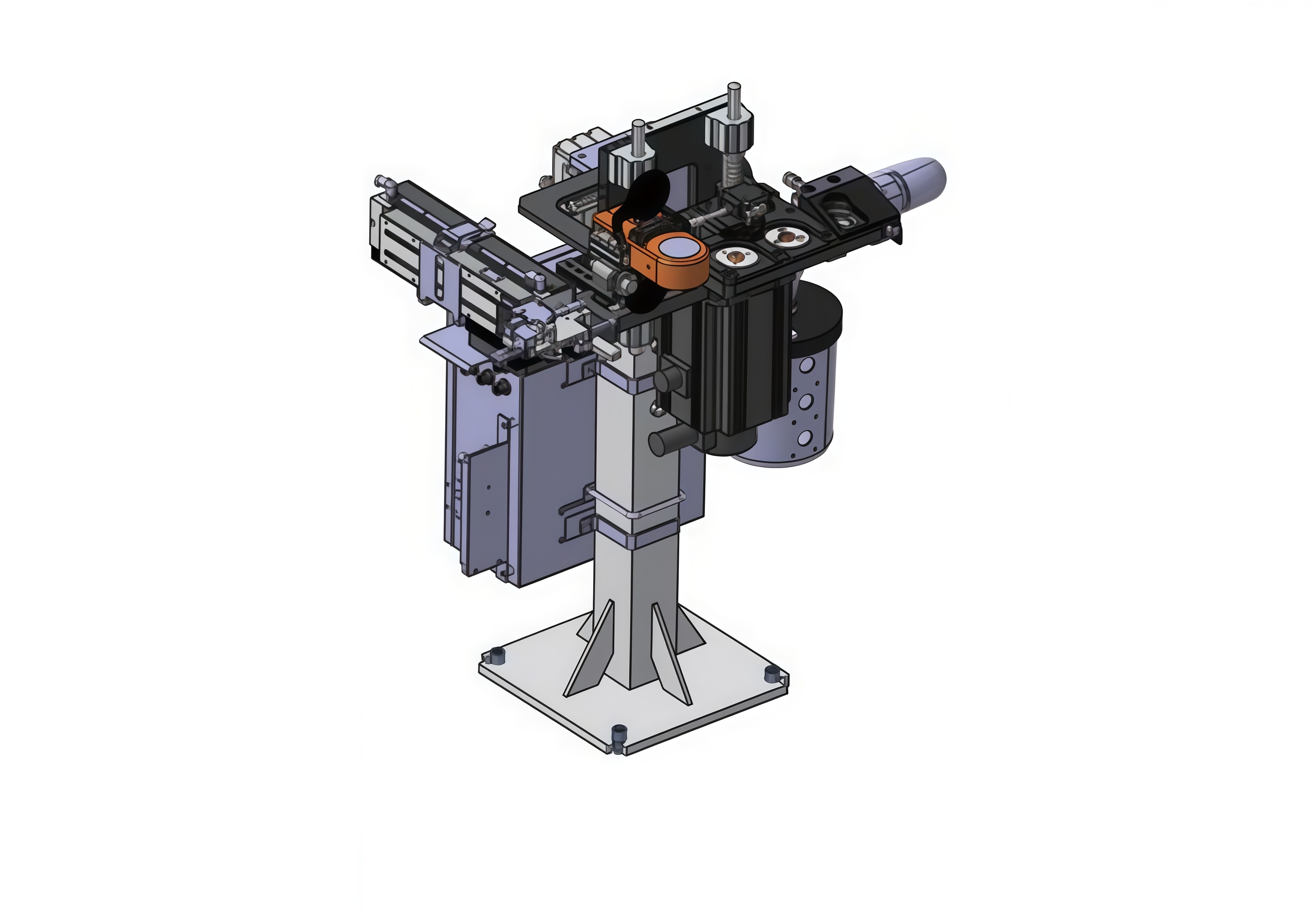

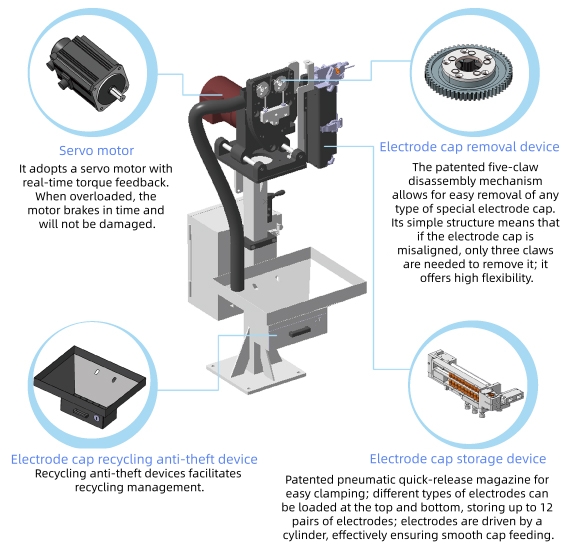

This product is specifically designed for automated welding production lines and only features electrode cap removal; it lacks a grinding function. It employs a servo motor drive and worm gear transmission, with five ratchet pawls forming a balanced removal structure to ensure even force distribution and smooth operation during the removal process. The product comes standard with a pneumatic quick-release magazine, enabling automatic removal and retrieval of the electrode cap.

This product is specifically designed for automated welding production lines and only features electrode cap removal; it lacks a grinding function. It employs a servo motor drive and worm gear transmission, with five ratchet pawls forming a balanced removal structure to ensure even force distribution and smooth operation during the removal process. The product comes standard with a pneumatic quick-release magazine, enabling automatic removal and retrieval of the electrode cap.

产品特点:

A.Servo Drive and Real-Time Feedback: Utilizes a 220V single-phase servo motor drive with real-time torque feedback. In case of overload, the motor can brake promptly, effectively protecting the equipment.

B.Dedicated Disassembly Mechanism: Employs a five-jaw balanced disassembly structure, which is compact, easy to operate, and has a wide disassembly range suitable for electrode caps from Φ13 to Φ20mm.

C. Safe and Reliable: Equipped with an electrode cap disassembly and assembly detection system, providing full monitoring to ensure safe, reliable, and precise disassembly operations.

D. Multiple Installation Positions: Offers horizontal, vertical, and upright installation positions to flexibly adapt to different welding clamp types.

E.Flexible Communication Interface: Equipped with external ports to meet various on-site communication needs. The standard port is a 24VDC NPN type IO, with optional mainstream industrial buses such as DeviceNet, Profinet, and Profibus.

F.Anti-Theft Recycling Design: Includes a built-in anti-theft device for electrode cap recycling, facilitating recycling management and on-site 5S practices.

设备参数:

| 品牌 | 红白 |

|---|---|

| 模型 | HBXMQ-007 |

| 额定输入功率 | 1.3千瓦 |

| 电源 | Single-phase AC 220V ±10% |

| 接地方法 | TN-S |

| 相电流 | ≤10A |

| 拆卸速度 | 20 – 120 rpm(可调) |

| 研磨速度 | |

| 开盖时间 | 22秒 |

| 电极尺寸 | 13-20毫米 |

| 扭矩 | |

| 电极帽盒数量 | The magazine can hold up to 12 pairs of electrodes.. |

| 尺寸 | |

| 重量(公斤) | |

| 全球贸易项目编号 (GTIN) | |

| 原产国/地区 | 中国 |

| CE认证 | |

在线联系

在线联系