Product Introduction:

This spot welding machine utilizes the powerful information processing capabilities of high-speed DSP microprocessors to achieve fully digital power management and fully closed-loop current control technology, improving time resolution and current control accuracy. The use of medium frequency (1-2kHz) inverter technology and secondary rectification technology ensures that the output current is not affected by the output circuit. Compared with power frequency welding machines, it has the characteristics of high thermal efficiency, large output power and low welding spatter. Its adaptive function has a large application space and strong robustness, that is, a welding clamp can adapt to the welding needs of different thicknesses of plates in one workstation, and can be adapted to the welding of ordinary cold-rolled plates, galvanized plates, hot-formed steel plates, and high-strength plates. It is widely used in the fields of automobiles, automotive parts manufacturing, hardware sheet metal industry, household appliances, low-voltage appliances, aerospace, and military industry. This welding machine combines intelligence, efficiency and energy conservation, making it a promising energy-saving product and a technological breakthrough in the field of resistance welding.

Product Features:

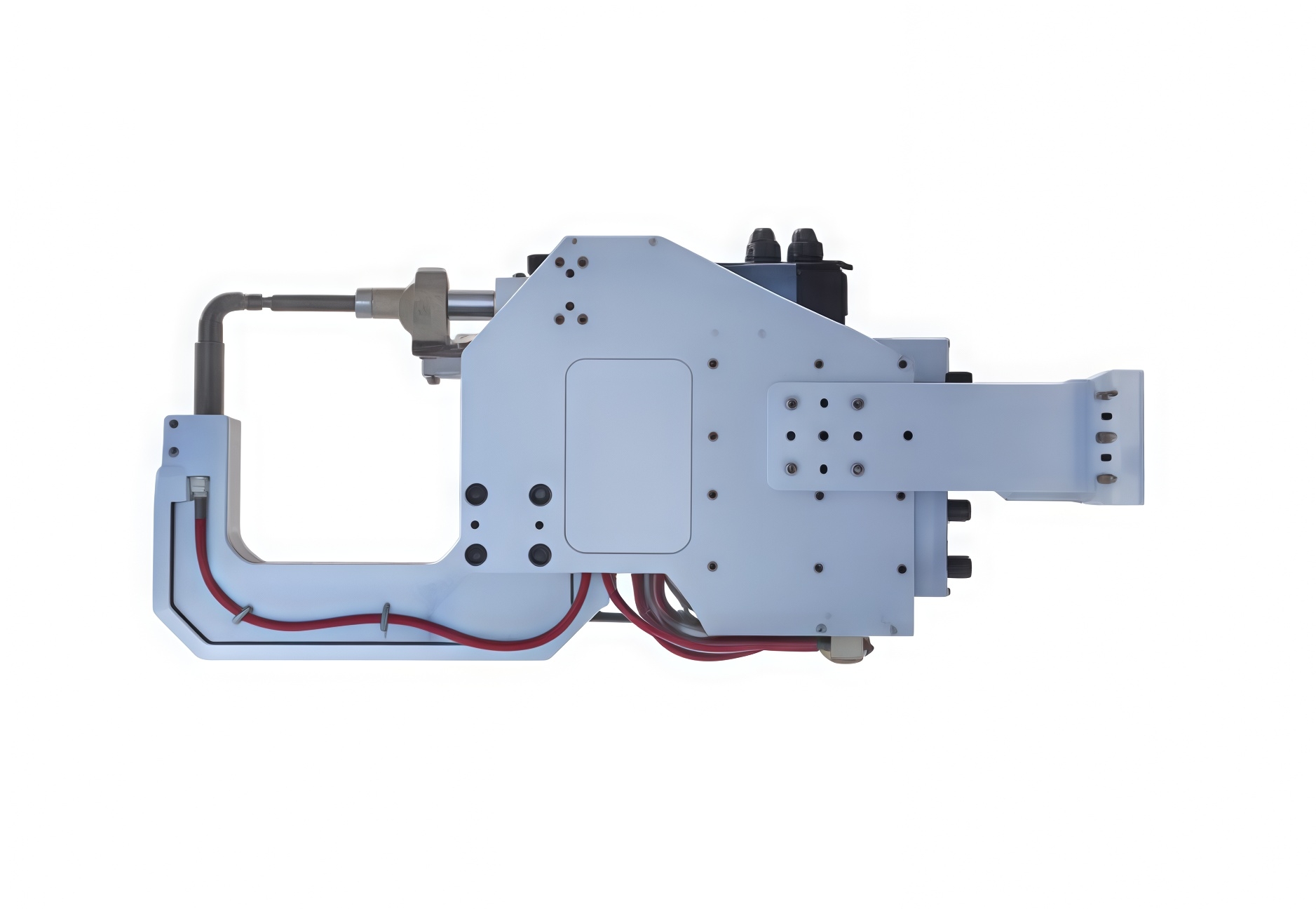

1. Welding transformers are small and light, easy to integrate with welding clamps; The hanging structure is made of high-quality aviation aluminum, and its three-dimensional rotating structure optimizes the flexibility and reliability of welding operations.

2. The welding clamp adopts a proportional valve to control the pneumatic servo mechanism, which can achieve adaptive control of welding pressure and welding current, and realize two or more different welding processes for a single welding clamp at the same workstation.

3. When carrying ultra large welding clamps, the main structure is made of aviation aluminum and high-quality copper materials, which are finely processed to achieve good rigidity and strength under lightweight structure.

4. The welding controller has good adaptability to the power grid and strong anti-interference ability.

5. Compatible with two main types of welding clamps (C-type and X-type), various complex workstation operation requirements can be achieved through different structural design and simulation of the welding arm.

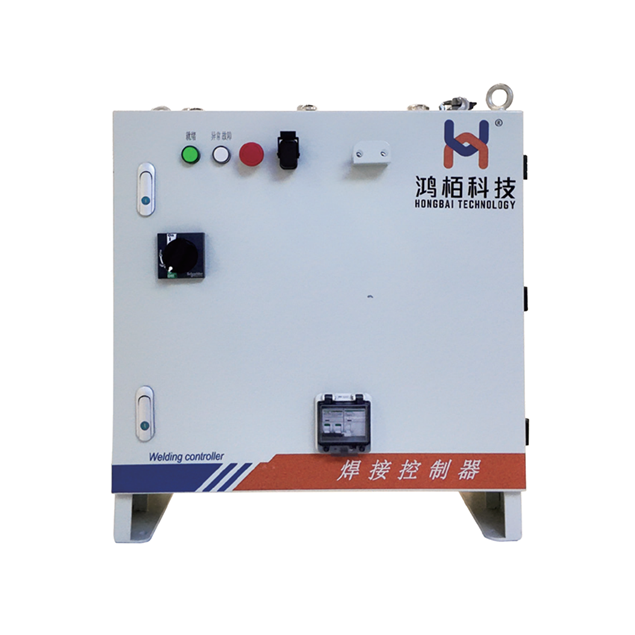

BASIC CHARACTERISTICS OF CONTROLLER:

| Brand | HongBai |

|---|---|

| Input Characteristics | Three-phase380V±15% 50~60Hz |

| Output Characteristics | 540V±15% |

| Rated Load Rate(A) | 600A |

| Current Control Accuracy | 1.5% |

| Insulation Class | F |

| Working Mode | Manual |

| Cooling Method | Forced air cooling |

| Rated output power | 180KVA/20% |

| Inverter Frequency (kHz) | 1-2 |

| Rated Load Rate | 20% |

| No-load Loss (kW) | ≤0.07 |

| Protection Class | IP54 |

| Clamp Interface(C-type/X-type) | One to one, one to two |

| Available Transformer Models | BD1-105、BD1-135、BD1-175 BD2-105、BD2-135、BD2-175 |

| Size | 650mm×845mm×480mm |

| Weight (kg) | 90±10 |

| Global Trade Item Number (GTIN) | |

| Country/Region of origin | China |

| CE certification | Yes |

Online Contact

Online Contact