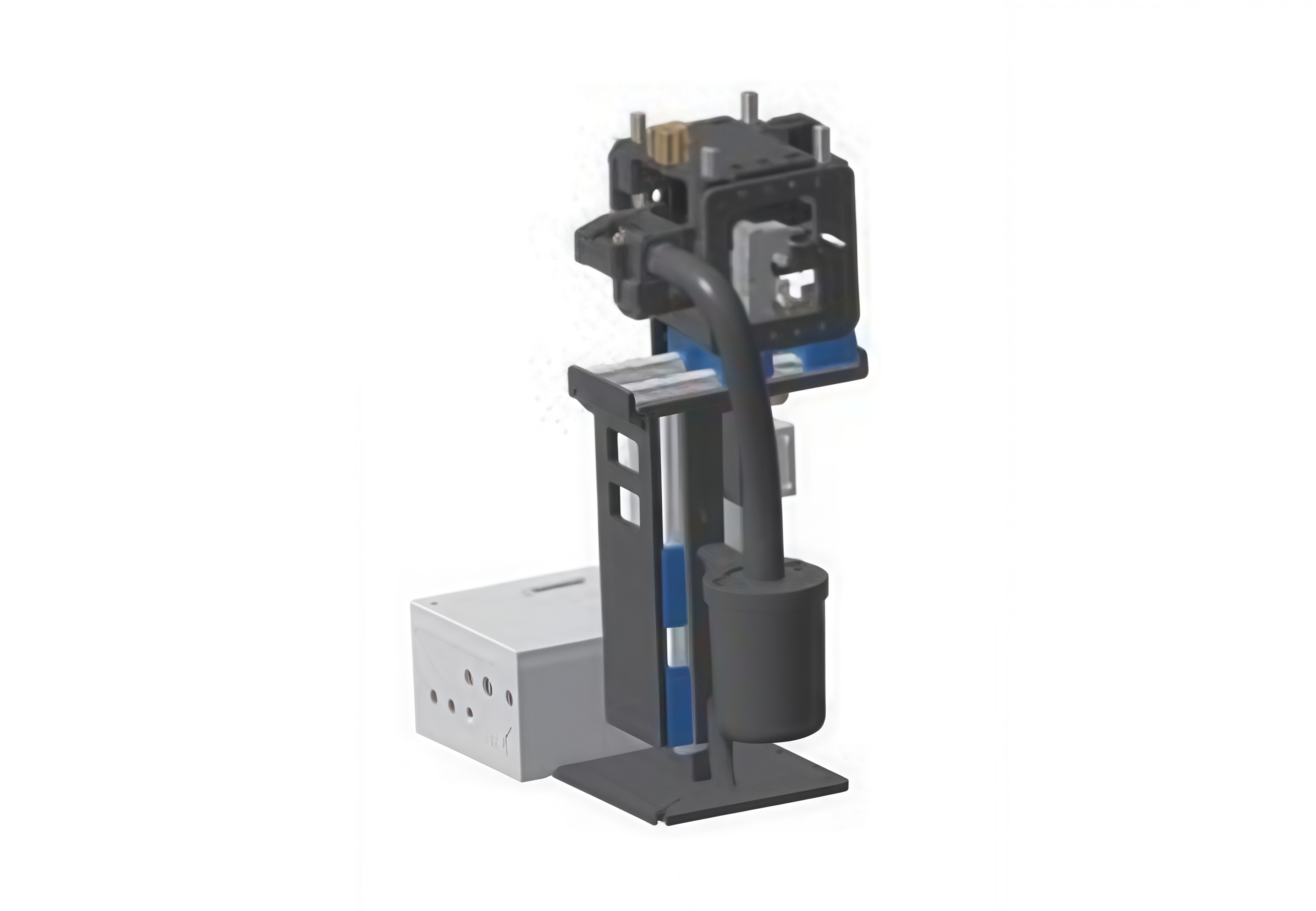

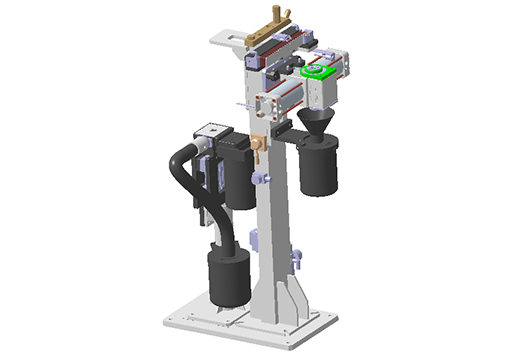

The external communication interface of this product supports IO port and various bus interfaces (configurable according to site requirements). The use of carbide coated blade can achieve high speed dressing. It can dress the upper and lower electrode cap at the same time to achieve the electrode end faces concentric and coincide after repairing. The dresser has the functions of automatic disassembly, automatic delivery and installation of the electrode cap, and ensures the work neat and tidy with an automatic copper chip collector.

Product features:

Driven by a 220V servo motor, the grinding speed is adjustable from 0 – 650 RPM to complete two actions: electrode cap grinding and replacement.

It has a stable five – jaw disassembly structure and is standard – equipped with a pneumatic magazine for electrode caps with a diameter of Φ13 – Φ20mm.

The two actions of grinding and replacement can be completed within 30 seconds, featuring high efficiency.

It is equipped with a feedback system for various function information, making the grinding and replacement more reliable.

It is equipped with external ports to meet different on – site communication requirements.

Standard ports: 24VDC PNP type IO; optional Devicenet, Profinet, Profibus, etc.

Device parameters:

| Brand | HongBai |

|---|---|

| Model | HBXMQ-003 |

| Rated input power | 1.3KW |

| Power supply | Single-phase AC 220V±10% 50HZ±2% |

| Grounding method | TN-S |

| Phase current | ≤10A |

| Disassembly speed | 20 – 120 rpm (adjustable) |

| Grinding speed | 300-500rpm |

| Cap removal time | 22s |

| Electrode size | 13-20mm |

| Torque | 30N.m |

| Number of magazine electrode caps | There are 12 pairs in total, upper and lower. |

| Size | |

| Weight (kg) | |

| Global Trade Item Number (GTIN) | |

| Country/Region of origin | China |

| CE certification | Yes |

Online Contact

Online Contact