Product Introduction

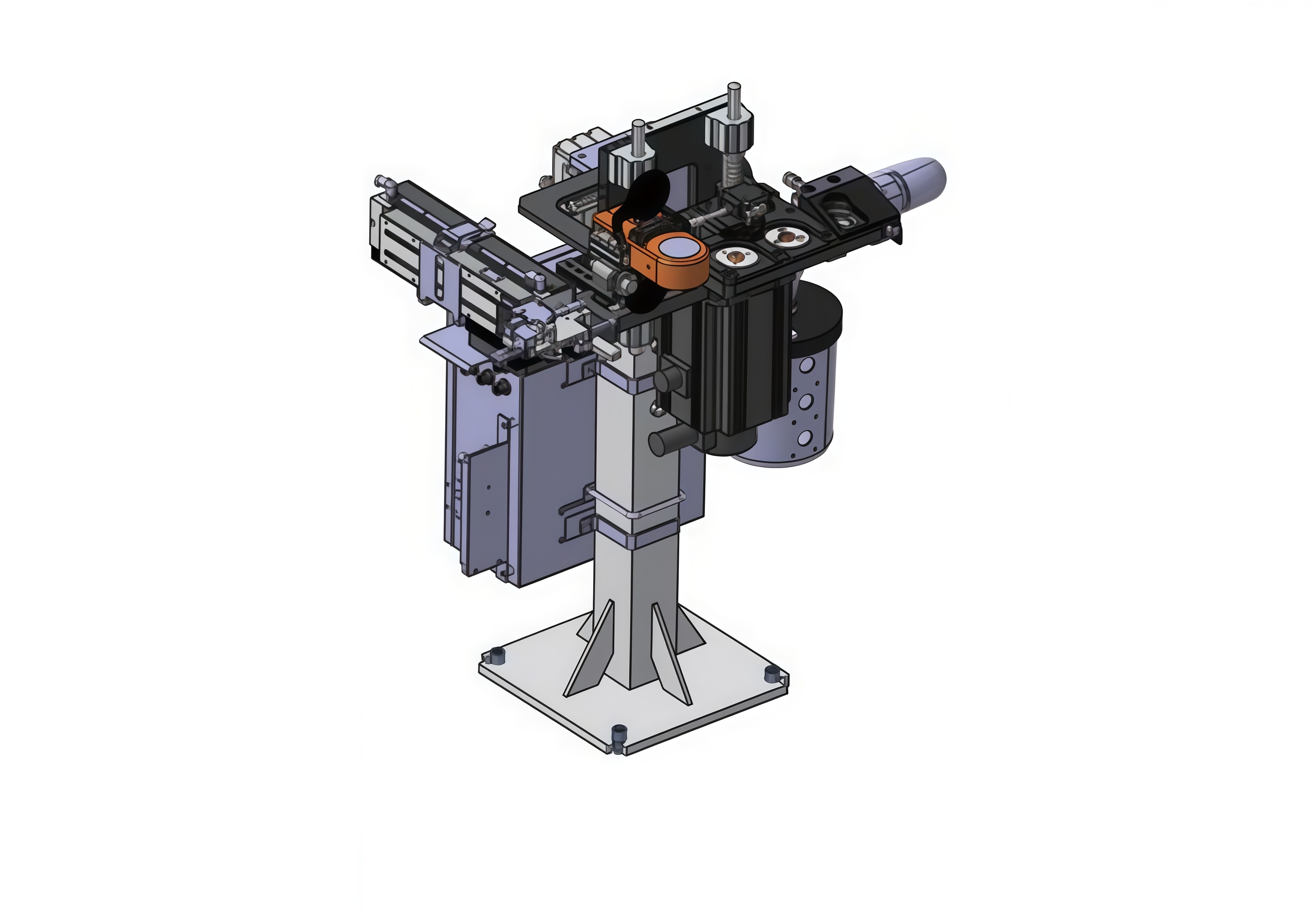

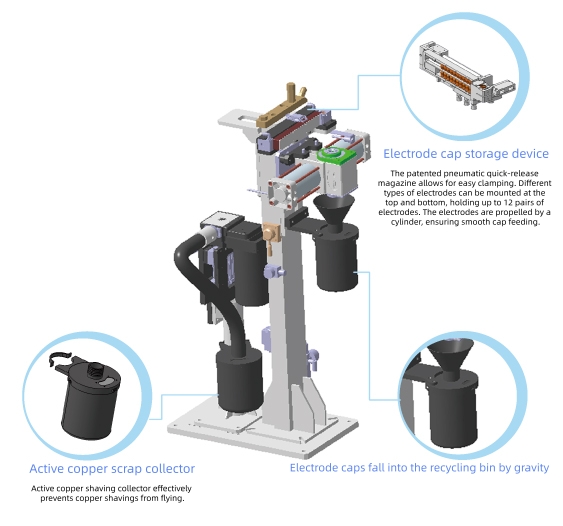

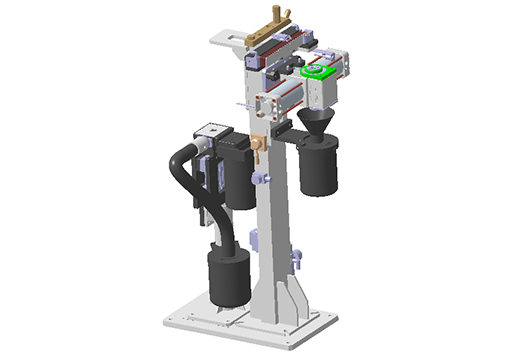

This integrated single-sided welding electrode cap grinding and replacement machine is a fully automatic electrode cap grinding machine designed for single-sided welding torch production lines in the automotive body-in-white industry. This grinding machine features pneumatic electrode cap removal, pneumatic clip supply of electrode caps, automatic electrode cap grinding, and post-grinding auxiliary inspection, improving the automation rate of the production line.

Product Features

- Driven by a 380V three-phase motor, grinding speed 280RPM.

- Can disassemble and grind electrode caps from Φ13 to Φ20mm.

- Grinding and replacement can be completed within 30 seconds, high efficiency.

- Equipped with a multi-function information feedback system for more reliable grinding and replacement.

- Equipped with external ports to meet different communication requirements on site.

- Features a grinding cylinder, pneumatic electrode cap removal, and pneumatic clip supply of new electrode caps.

- Standard port: 24V DCPNP type IO; optional Devicenet, Profinet, Profibus, etc.

| Model | HBXMQ-009 |

|---|---|

| Rated Input Power | 1.3KW |

| Power Supply | Three-phase AC 380V±10% |

| Frequency | 50HZ±2% |

| Grounding Method | TN-S |

| Phase Current | ≤10A |

| Disassembly Speed | |

| Grinding Speed | 300-500rpm |

| Cap Removal Time | |

| Electrode Size | 13-20mm |

| Swing Arm Drive Method | |

| Swing Arm Angle | |

| Torque | |

| Number of Magazine Electrode Caps | |

| Compressed Air Pressure | 0.4Mpa-0.6Mpa |

| Grinding Pressure | 0.9-1.2KN |

Online Contact

Online Contact