Product Introduction

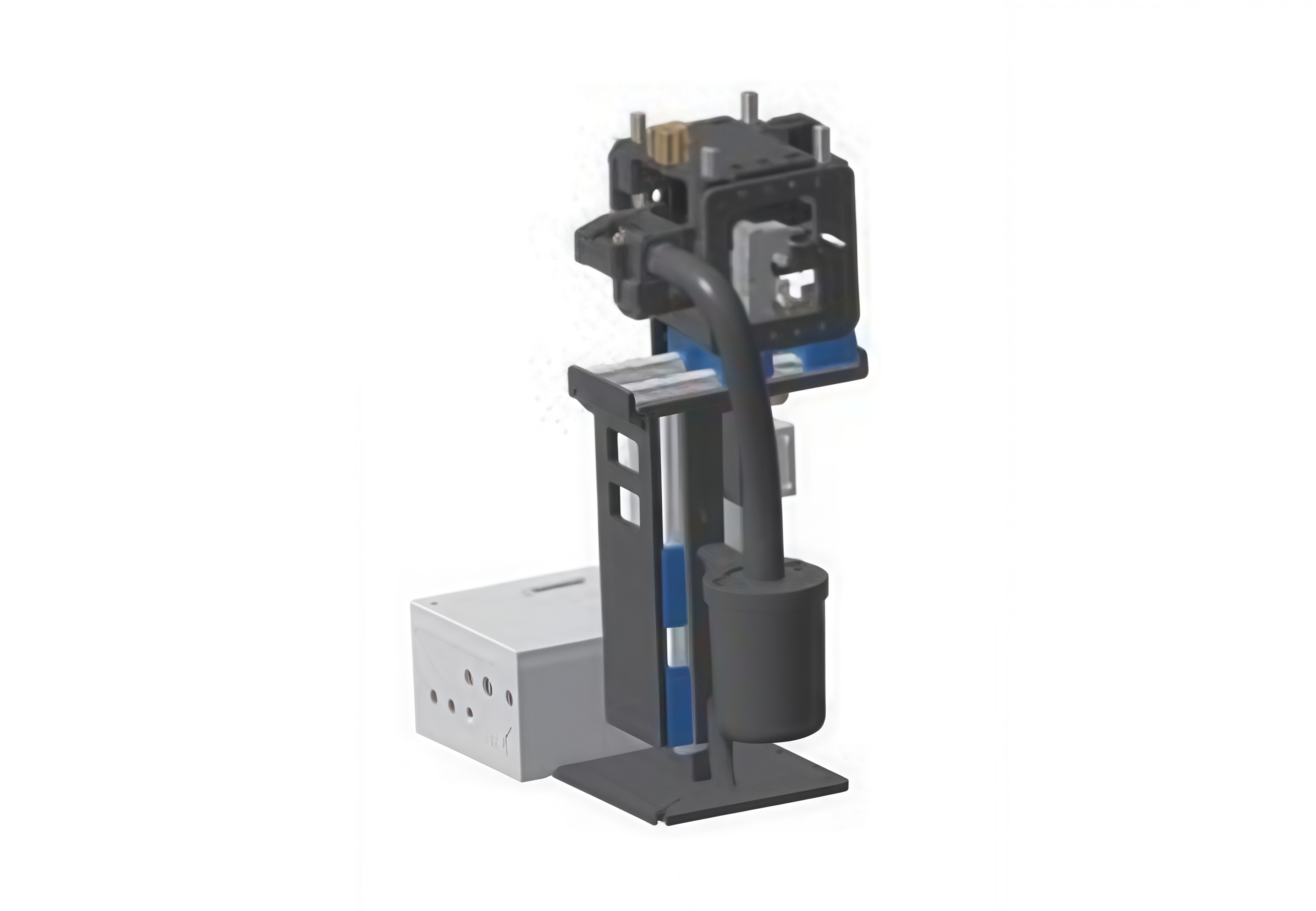

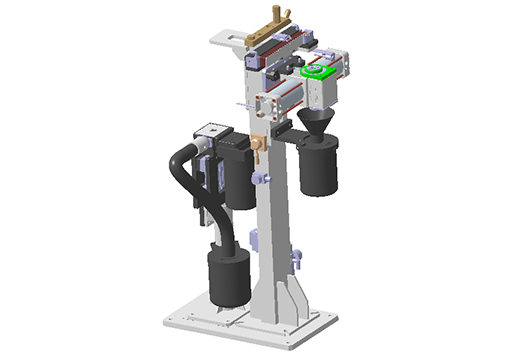

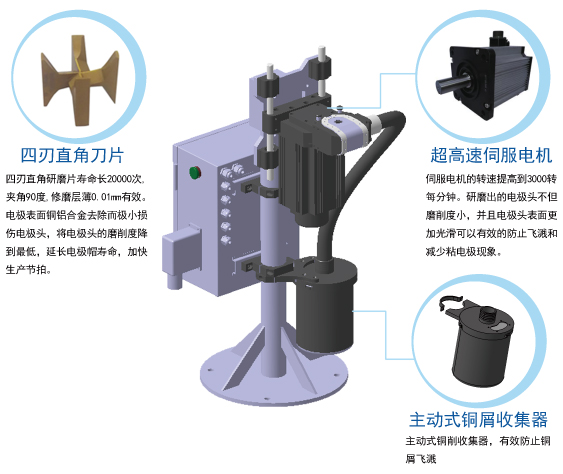

This product supports hard I/O ports and various bus interfaces for external communication (configurable according to site requirements). It uses carbide coated blades, enabling high-speed regrinding and simultaneous regrinding of the motor caps on both the upper and lower motors of the spot welding clamp, resulting in concentric and perfectly aligned electrode end faces.It features automatic electrode cap removal, automatic electrode cap feeding and installation, and an automatic copper shavings collector, ensuring a clean and aesthetically pleasing work environment.

Product Features

- Ultra-high-speed servo motor drive, grinding speed 1500-3000 RPM.

- Equipped with carbide four-blade inserts, tungsten carbide surface treatment, high blade hardness, and long lifespan.

- Equipped with a torque monitoring system; detects torque increase and stops rotation when torque decreases, protecting the electrode rod.

- Possesses all the functions of an electrode grinding machine.

- Equipped with external ports to meet different on-site communication requirements.

- Standard port: 24V DCPNP type IO; optional Devicenet, Profinet, Profibus, etc.

Product Specifications

| Model | HBXMQ-008H, HBXMQ-008L, HBXMQ-008 |

|---|---|

| Rated Input Power | 1.3KW |

| Power Supply | Three-phase AC 380V±10% |

| Frequency | 50HZ±2% |

| Grounding Method | |

| Phase Current | |

| Disassembly Speed | |

| Grinding Speed | 1500-3000rpm Cap |

| Removal Time | |

| Electrode Size | 13-20mm |

| Swing Arm Drive Method | |

| Swing Arm Angle | |

| Torque | |

| Number of Magazine Electrode Caps | |

| Compressed Air Pressure | |

| Grinding Pressure | |

Online Contact

Online Contact