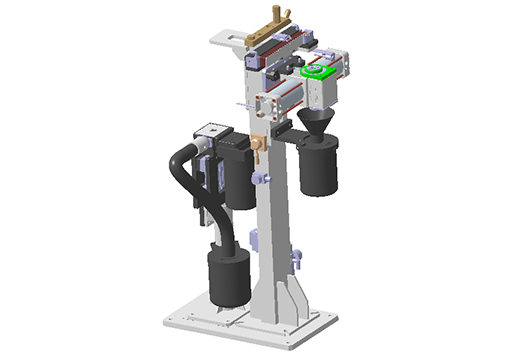

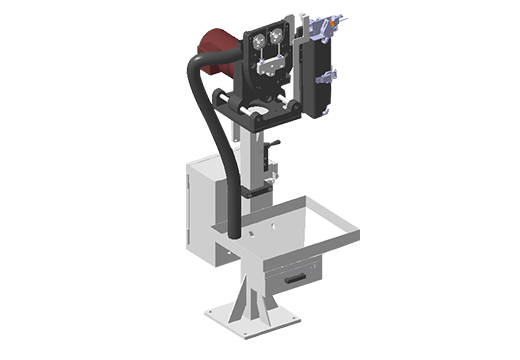

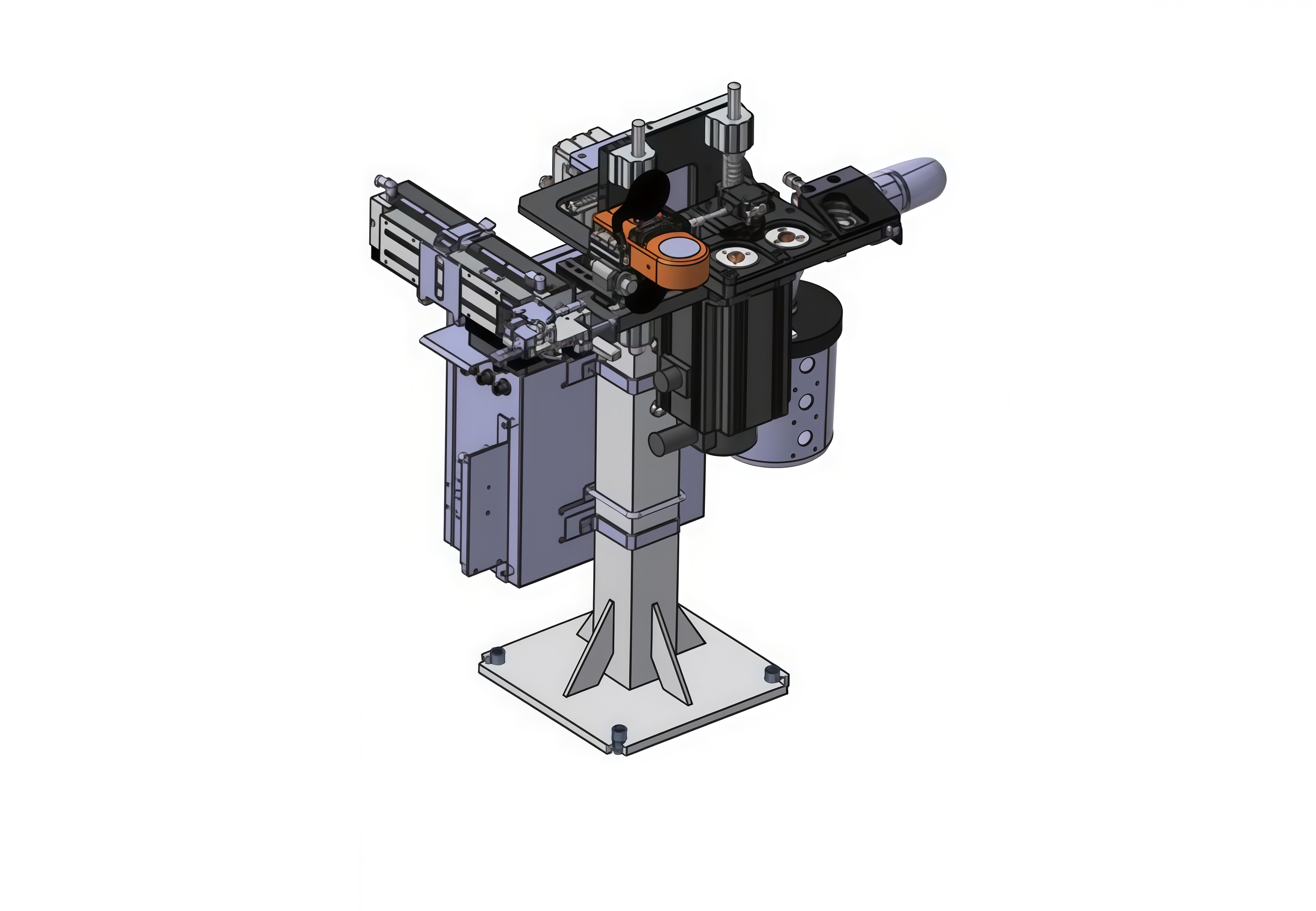

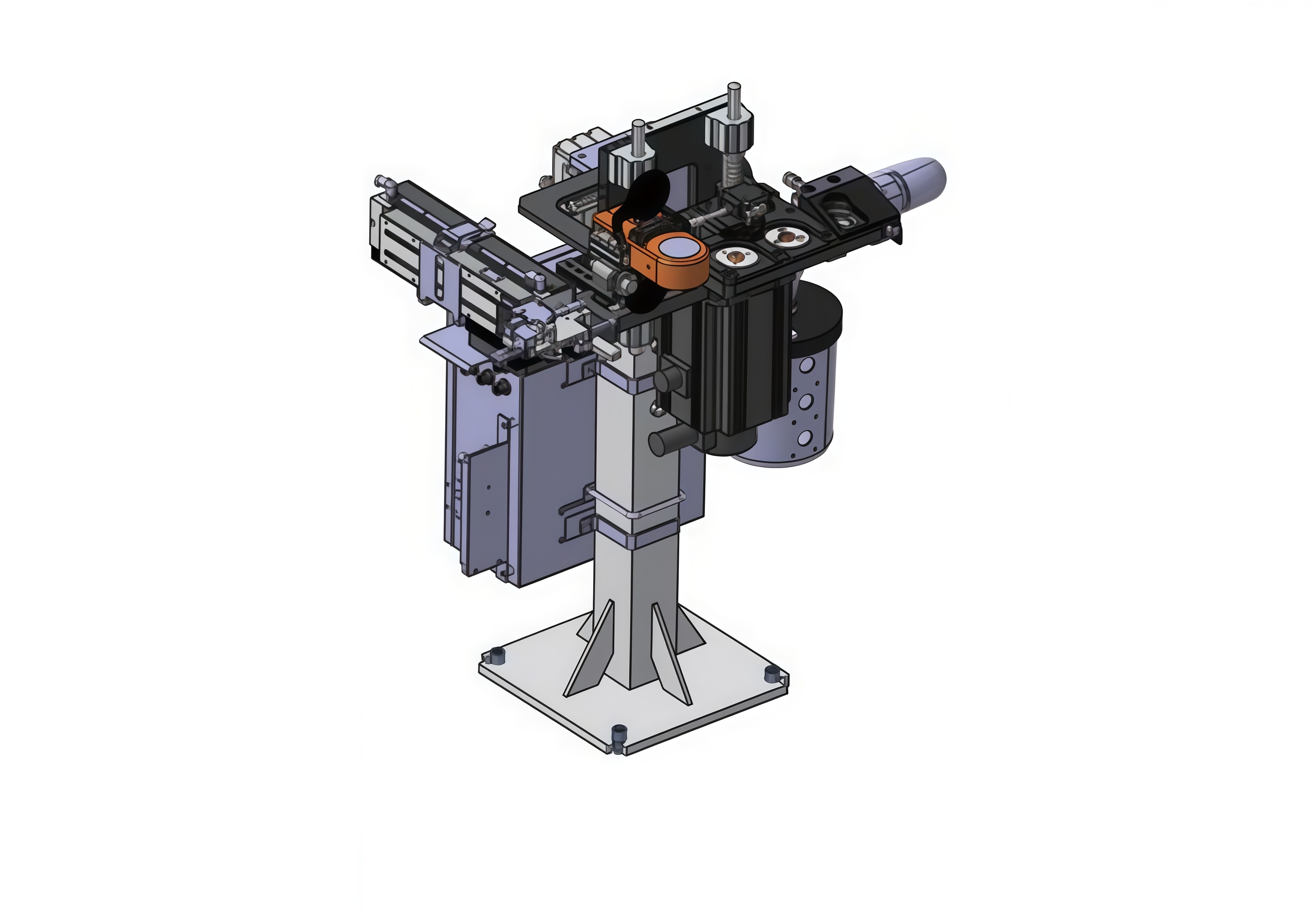

System Composition:

AI Vision Electrode Cap Grinding and Inspection Sensor: Employs a high-resolution imaging module with high pixel density and a fast frame rate.

Industrial Control Computer and Software System: Runs AI vision inspection software with multiple built-in AI models.

Auxiliary Equipment: Includes a pneumatic control module, PLC control system, electrical cabinet power supply, etc.

Features

- Integrated Intelligent Grinding and Real-Time Quality Inspection: Driven by a 220V servo motor, the grinding speed is adjustable from 0-650 RPM, efficiently completing the grinding and replacement of electrode caps. After grinding, a high-resolution AI vision sensor automatically completes quality inspection within 1 second, identifying various defects such as black marks, dents, and copper filings.

- Reliable Automated Actuator: Featuring a stable five-jaw disassembly structure and standard pneumatic clips, suitable for electrode caps from Φ13 to Φ20mm, ensuring accurate and reliable replacement.

- High Efficiency Throughout the Process: The entire process, from grinding and replacement to visual inspection, can be completed within 30 seconds, significantly improving the automation cycle time and efficiency of the production line.

- Full Information Feedback and Closed-Loop Control: Not only is it equipped with a feedback system for various functional information (such as torque and speed), but it also provides intuitive grinding quality data and image reports through an AI vision system, achieving a complete and reliable closed loop from “execution” to “verification.”

- Flexible Industrial Integration Capabilities: Equipped with abundant external ports to meet different communication and control requirements on-site, facilitating integration into smart manufacturing networks.

- Standard and Optional Communication Protocols: Standard Port: 24VDC PNP type IO; Optional mainstream industrial bus protocols such as DeviceNet, ProFINET, and Profibus, and can upload inspection data to the upper-level MES/SCADA system.

- Core AI Vision Functions: High-Precision Inspection: Inspection accuracy up to 0.01mm, capable of identifying more than ten defects such as end face non-roundness, eccentricity, and uneven grinding. Data Management and Analysis: Automatically saves the results and images of each inspection, supports historical data traceability and statistical analysis, providing a basis for process optimization and predictive maintenance. Non-Contact Inspection: Avoids secondary damage to electrode caps, ensuring objective and consistent inspection results.

Online Contact

Online Contact